Printing materials

There is a vast amount of materials available for printing.

Most printers are compatible with a lot of materials but some printers cannot use the high temperatures needed for ABS and other materials. Please check your printer's specs before ordering materials.

Other materials, like Arnitel or other flexible materials, cannot be used on printers with a bowden extruder - although some bowden printers may be able to print with these materials.

I have a printer with an E3D Titan extruder with an E3D v6 hotend, with this combination almost all materials can be printed.

Note that some materials like Woodfill do not work with small nozzles, I suggest a nozzle size of 0.6mm with woodfill. Materials like Carbonfill are abrasive and for this material a stainless steel or a hardened steel nozzle is needed. A standard brass nozzle wears out very fast and won't last for many hours.

Examples of this are Laywoo, for which a bigger nozzle is needed, or Arnitel, which is too flexible to be handled by the standard extruder mechanism from Leapfrog.

I have the spring loaded mechanism on both the extruders and although I think that all materials will also work with the standard (fixed distance) extruder from Leapfrog it may need some adjustments when using especially softer materials like Nylon or Arnitel to get more pressure or less pressure when using harder materials like PET.

Changing materials

Always clean the hotend when changing materials.

When the new material has a lower temperature than the old one, heat up the extruder to the high temperature of the first material and extrude at least a few centimers of the new material before lowering the temperature to the needed value. Any old material left may block the nozzle.

If problems persist, remove the nozzle and replace it with a new one or clean the old nozzle.

I clean my nozzles with a 2mm drill and a thin steel wire. First heat up the nozzle using a lighter - or a small gas torch - and then remove any excess material with the drill. DO NOT USE A POWER DRILL, clean the nozzle manually with just a drill bit. Never scrape any metal from the nozzle, you only need to remove the plastic material in the nozzle.

After this I use the steel wire to clean the inside of the nozzle tip. For the outside I only use a paper tissue. Never use a knife or other sharp objects to scrape burned materials from the outside of the nozzle. I sometimes use emerald cloth to clean excessive burned nozzles but this should be left to experts.

ABS Low Warping

ABS-LW is a new (July 2016) material from MakerPoint (available here). Like ABS this is usable for structural parts but there is less warping during the printing process. Due to this the the material is easier to print, has a good bed adhesion and deliveres better layer adhesion resulting in stronger parts.

It is more expensive that regular ABS (€ 35,- compared to € 25,- for regular ABS) but as soon as you start using ABS-LW, you will notice that the low warp properties improve the print quality. This is true even for small parts. On all my ABS parts I notice at least tiny bits of warping around the edge. With ABS-LW this may still happen on large objects but even my 75mm long, 14mm high test piece did not show any warping during printing.

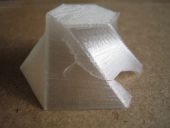

Below are two photos of the part used to test ABS-LW. This is a long, thin-walled, high part (75 x 1.5 x 14mm) with a part that needs some support. On the white (standard ABS) part there is clearly a lot of warping. There was a 3-4mm gap on the right side. The black part is the finished part. Even after cooling down and removing the part from the bed there was no warping at all.

ABS-LW can be printed with the same parameters as ABS, just increase the temperature, and support is as easy to remove from the parts as with regular ABS.

I currently print most parts in PETG, but ABS-LW is even easier to use and delivers a print quality that is a bit better when support or larger overhangs are used.

ABS-LW prints at temperatures between 240 and 260°C with minimal cooling.

PC-ABS

Polycarbonate is a high impact technical plastic used for special applications. I regularly use 3mm PC sheet material for mechanical constructions. It is easy to mill or drill and you can even bend this material just like thin metal sheet (cold, in a bending press). It is almost impossible to break.

Combined with ABS this is a material for high impact strength structural parts.

I have a sample pack with this material but have not used it.

ABS-PC prints at 270°C

ABS

ABS is available in a range of colors.

One color that is a bit different than the others is white. Some companies sell natural ABS (without any coloring additives) but the still call this white or most of the times white/natural. RepRapWorld sells both (when available) the natural ABS and a true white ABS with coloring additives. The last is shown in the product overview as "White ABS" and on the product page the description mentions that this ABS is "not just white, but really white".

Plastic2Print consistently uses the terms natural and white for both materials.

ABS prints at temperatures between 220ºC and 275ºC.

With a too low temperature, the layers do not weld together enough resulting in delamination. When the tempareture is too high, the material stays warmer for a longer time and that may result in warping due to cooling problems. This may result in problems with overhangs dropping down and will also result in a too good bonding with the raft: after printing the raft should come of fairly easy but it should still be well connected to the object.

Different colors have different flow properties. Natural ABS flows very smoothy whereas I need to push harder on Dark Green filament to get it extruded.

While most colors print perfectly at 235°C, some colors print better at a lower temperature. My yellow filament prints nicer at 225°C. Each new spool I buy, even the same color, has to be tested again to find the new color.

PLA

PLA is a material that is made of starch. This can be from corn or any other material like wheat or potatoes. PLA is a bio-degradable material but this does not mean it is not suitable for objects that you want to keep for a longer time, it even makes a very fine material for printing.

PLA prints at lower temperatures (180ºC - 210ºC) and gives a more shiny surface than ABS.

Compared to ABS, PLA becomes a thinner 'liquid' when it is melting. Also, ABS goes from solid to liquid in a small temperature range whereas PLA first becomes jelly and then more gradually gets liquified. Leaving PLA in a heated extruder for a longer period may result in the PLA burning, leaving you with a clogged nozzle. Be sure to turn the hot-end off when printing stops to prevent this.

There are a few advantages above a material like ABS:

- PLA cools down faster resulting in less hanging when bridges are being printed.

- Has less thermal expansion. This results in better bridging possibilities and less warping of objects when cooling down.

- Layers of PLA weld nicer resulting in a smoother surface structure.

- PLA is less flexible than ABS, even thinner parts have a good stability but it still is tough and does not break that easy.

I am printing PLA at 210°C giving a very nice result. When I bought PLA I was looking for an orange color but I got a semi-transparent orange type and i discovered that most colors were not as bright as ABS. Nowadays PLA can be as bright and shiny as ABS and from a distance it is hard to see the difference.

PLA/HPA

PLA/HPA is a special mix made bij ColorFabb.According to ColorFabb's website, this material is a "Soft Touch PLA Compound with extended elongation". I do not feel a real difference between the PLA/HPA mix or plain PLA, it might have a bit of a "soft touch" but this may just be a suggestion becaus I want it to feel different.

The extended elongation is very clear when unpacking the material. Normal PLa or ABS filament breaks when bending it a few times but this material is more flexible, it stretches more than normal PLA or even ABS.

The material prints a bit nicer than regular PLA, it smoothes out a bit between layers giving a nicer finish than regular PLA or ABS.

ColorFabb already states in their logo "fabulous colors" and the colors indeed are fabulous. The orange is much brighter than my ABS and even the Cube orange, which is a very nice orange, is not as shiny as the ColorFabb material. Most colors have a RAL or even a Pantone number on the box. White is RAL9010 so this is a warm white and not a real (paper) white, Sky Blue is RAL5015 and Lila is Pantone 2725C. I am not sure however if these colors are constant between batches, the color is on the box but not on the website.

Nylon

Nylon is a very technical fiber. It is a co-polymer that bonds very well but it is hard to stick to the print bed.

Although nylon is available in many forms (e.g. weed whacker wire) I only use the high quality materials from Taulman 3D. Remember when ordering through Taulman3D directly that the prices on the website are excluding taxes (VAT and import duties) and that shipping costs can be extremely high ($ 59.90). I order my filaments through Plastic2Print in the Netherlands and within the netherlands there is a next day delivery.

Taulman has 2 types of Nylon. Not knowing which one to choose I ordered both:

- 618 - white with a translucent finish

- 645 - translucent white

The 645 is indeed translucent whereas the 618 has a milky white finish.

I tried printing both, 618 prints fairly well at ABS settings (at 235ºC) but the top solid infill is a bit rough. With the 645 I don't have any results yet since the hot end blocks each time. It looks like 645 settles in the hot end when it is left there.

The 618 is more runny than ABS and there is a lot of oozing when I stop printing. In one of my testing parts there is a bit of webbing on the inside due to this.

It seems like 618 expands more than ABS when leaving the extruder. An extruded filament is wider than with ABS. Holes come out too small and external dimensions are too big, much more than with ABS is the case.

This needs more testing to get proper parameters.

After testing it seems like higher speeds result in a smoother finish. For now the ABS settings seem to work well (High Quality - no support setting in slic3r from Leapfrog)

Arnitel

Arnitel is a family name of materials.

I got some Arnitel natural filament (45 shore D) to test from plastic2print.

Arnitel is a flexibel copolymer developed by Applied Polymer Innovations (API institute), a DSM company.There is a whole range of materials available but the ones sold for 3D printing are "Arnitel® Eco L-X07095 TPC" with a 40 shore D hardness and "Arnitel® Eco L-X07135 TPC" 45 shore D.

Plastic2print sells these under the name "Flex-PolyEster" or "FPE", the DSM website names this material FPC. DSM calls this "ThermoPlastic Copolyester" or "TPC" and sometimes it is called "TPE" for "Thermo Plastic Elastomer".

I have been told that both materials print at "about the same temperature as PLA" and the DSM Arnitel website mentions a melting temperature of 158ºC (40D) and 180ºC (45D).

I have not yet tried Arnitel, as a result of my tests with Nylon I want to create a new nozzle with a longer 0.3 mm channel. The current nozzle has a very short (estimated 0.5 mm) section of 0.35 mm and does not give me the perfect quality I am looking for. Multiple sources mention that a channel of 1-2 mm (with a 0.3 mm nozzle) should give better results.

PETG

PET is well known from plastic bottles. It is available as a clear translucent material and has some nice properties.

Different modified versions of PET exist, PETG is a common variant which is clear thermoplastic that can be thermoformed or molded.

Heating and cooling PET has an effect on the transparency of the material. Standard PET forms a more crystalline material when allowed to cool slowly and this results in a opaque to white material.

PET filament is clear as glass and when extruded the extrusion is as clear as the original material.

That is true for an extrusion that is allowed to fall down freely or for the first layer that is printed on the glass bed. During printing the walls of the object form a ribbed surface similar as to what you can see with ABS and that means that a printed PET object will never have the same transparency as a molded part. The fact that the infill (even when specified at 100%) is not always resulting in a full weld makes this worse.

It may be possible to polish PET but I have not tried this yet. Flame polishing and mechanical (abrasive) polishing are techniques that are commonly used with PMMA, it might be worth trying this with PET to get transparent objects.

PET is a nice material to print: it has a wide temperature range and prints from 160°C to 210°C without any problems.I had no problems at all getting the material to stick to the glass plate, I use ABS slurry a lot and just rubbing the glass with a little it of acetone (leaving a slight ABS coat) give a perfect bond. I have to lift a corner of a printed piece to remove it from the bed. I accidentally increased the temperature all the way up to 260°C resulting in a lot of oozing and an opaque/white finish.

At 200°C the bonding with the raft is too good making it impossible to remove the raft from the object. Printing without a raft is no problem at all even for small parts.

I printed two small vases (just 20mm high) for testing with 2 perimeters with a very good bond between the layers.

The first prints were at 200°C, since PET has a wide temperature range I also tested this print at 160°C (0.15mm layer height).

The print comes out very nice and the finish is better than at 200°C.

Nobody likes to break those fine looking prints and this was an accident. But then I was very happy with the result of the damage: I was able to break the chip that came of in little parts along the layers (by bending along the layer lines) but the vase itself shows no delamination at all.

Something I am very happy with.

PVA

PVA is a water solluable material, perfect for support structures. PVA is hygroscopic, meaning that if you leave it out on the open air, it will absorb moisture and become soft and unusable in the end.

For this reason it has to be stored in a dry place when not used.

I bought my PVA from Plastic2Print, but not after checking that they are able to deliver fresh material that is stored properly. On my question about this I was told that PVA is packed in a vacuum bag and bubble wrap to keep it fresh. And when delivered I noticed that there is also a large bag of silica gel in the vacuum packaging.

The PVA is still not used and in its vacuum bag until the moment when I think I am ready to start using it.

On the roll of PVA is a label stating printing temperature and a batch number. Batch 20130401: most likely the first batch created in April 2013 (bought in June 2013 so very fresh material indeed).

There is no expiration date on the PVA, a lot depends on how the PVA is stored when nog being used. I tend to store PVA in an air tight container with a good amount of silica gel. It is hard to see from the PVA when it becomes unusable but the silica gel will get a pink color when absorbing moisture so that gives a good indication on when it has to be changed.

I have no indication at all about the expiration of PVA or how hygroscopic it actually is. Those little bags around washing powders are also made of PVA and we just store these in an open plastic bag under the kitchen sink for a long time (at least a few month). When handled with dry hands they just feel like any plastic but as soon as you have wet hands the PVA immediately becomes all slippery.

As soon as the vacuum bag is opened I tend to take a few pieces (a few meters) and just let them sit unprotected on my desk and in unprepared plastic bags - jus to see how long it takes before it becomes unusable when stored in the open.

When it becomes too wet for printing, it can be dried in a moderate oven (40°C) or in food drying equipment - this is also something to test: does it help to take protective measures by drying it on a regular basis (like once every 1-2 months)

LayWoo-3D

Laywoo-3D is a plastic material that contains wood fibres. As a result, Laywoo-3D is harder to print than other materials since the fibres may clog your nozzle.

A nozzle of 0.5 mm must be used to print Laywood, smaller nozzles will result in partial clogging. Laywoo is currently not recommended for the leapfrog Creatr, although some users have reported good results with Laywoo-3D

Woodfill

WoodFill is similar to Laywoo-3D but produced by ColorFabb.

It is a PLA material with 30% woodfibre and available with fine and course milled fibres. The course material is only available as 3mm filament and needs a 0.8mm nozzle to print.

Since woodFill contains fibres, a nozzle size of 0.4mm (0.35mm) is recommended as a minimum size and you have to use thicker layers. I suggest to use a layer height of 0.25 mm as a minimum, a smaller layer height may result in clogging your nozzle.Also take care not to leave your extruder switched on while not printing since this may clogg the nozzle. I recommend to only print woodFill (or laywoo-3D) while you are near your printer so you can stop printing as soon as you detect problems.

ColorFabb suggest a speed of 3000 mm/min with a minimum layer time of 8s and a retraction or 1.3mm with a speed of 1500 mm/min for the makerBot. On my Creatr I use a bit more agressive retraction (3mm at 1800 mm/min) with a printing speed of 3000 mm/min using a 60% outline underspeed in Simplify3D. Simplify3D does not have a minimum layer time, this is done using the Speed Override (on the Cooling tab) and I left this at its default values (adjust printing speeds belong 15s with 20%).

article about woodFill on 3dprintingindustry.com

How to print woodFill on learn.colorfabb.com

Overview of materials

| Material | Temperature | Use | Tested |

| ABS-LW | 240-260°C | Structural parts, can be drilled/tapped | yes |

| ABS | 210-250°C | Structural parts, can be drilled/tapped | yes |

| PC-ABS | 270°C | Structural high impact parts, can be drilled/tapped | no |

| PLA | 180-220°C | yes | |

| PLA/HPA | 195-220°C | Structural parts, flexes like ABS | yes |

| Nylon 618 | 235-270°C | Structurel parts, slightly flexible, can be tapped | yes |

| Nylon 645 | 235-270°C | Structural part, slightly flexible, and transparent, can be tapped |

yes |

| Arnitel 40D | Flexible rubber like, anti slip | no | |

| Arnitel 45D | Flexible rubber like, anti slip | yes | |

| PET | 160-220°C | Transparent parts | yes |

| PVA | 175°C | Soluable support | no |

| LayWood | 175-250°C | no | |

| Woodfill | 190-220°C | give an MDF wood type finish | no |